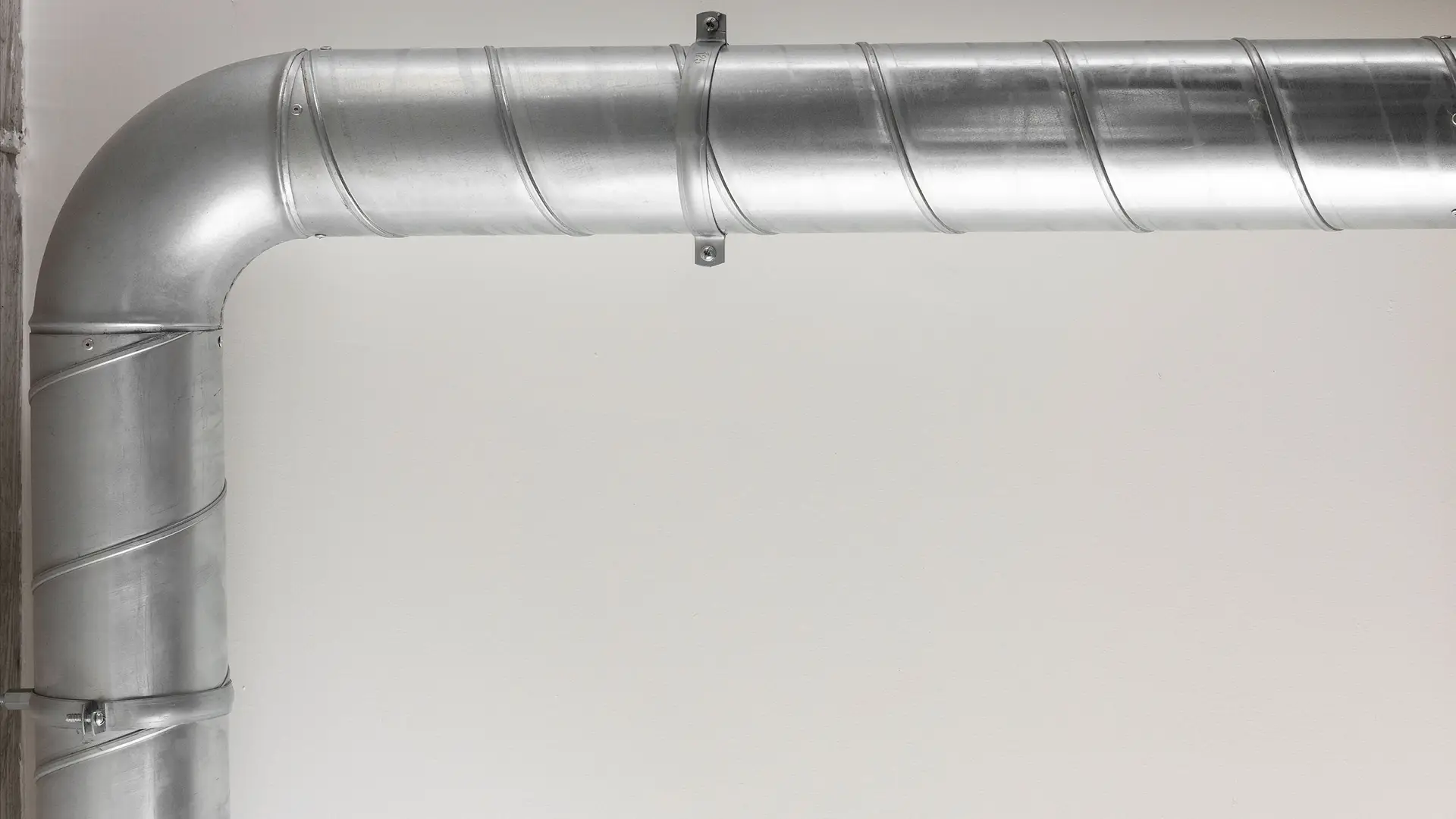

90° vs 45° Bends in Ducting: The Airflow Drop You Don’t See

When planning your cooker hood ducting, the number and shape of bends can dramatically affect airflowThe volume of air moved through the ducting, measured in cubic metres per hour (m³/h).. But the difference between a 90° and 45° bend is often underestimated.

How Bend Angles Affect Airflow

Every bend in ducting increases resistance — forcing your hood’s motor to work harder and reducing extraction efficiency. A single 90° bend can cut airflow by up to 30–50%, depending on duct length and hood power. In contrast, two 45° bends create a smoother curve that reduces turbulence and keeps air moving more freely.

When 90° Bends Are Unavoidable

Sometimes, tight kitchen layouts leave little room for gentle curves. If you must use a 90° bend, position it as far from the hood outlet as possible and ensure your ducting is smooth, short, and wide enough to handle airflow efficiently.

Pro tip:

Keep your total duct run under 3 metres where possible, and use CATA ducting kits designed for optimal performance and low noise.

The Bottom Line

For maximum extraction and quieter operation, choose 45° bends wherever space allows. Fewer sharp turns mean less turbulence, better suction, and a cleaner, more efficient kitchen environment.

- All Posts

- Cooker Hood Guides & Advice

- Dishwasher Guides & Advice

- General Appliance Guides & Advice

- Hob Guides & Advice

- Laundry Guides & Advice

- Microwave Guides & Advice

- Oven Guides & Advice

- Wine Cooler Guides & Advice

Discover everything about ceramic hobs in our go-to guide. Learn how they work, their benefits, and how to care for...

Find out why turning off appliances at the wall saves energy, reduces bills, and helps prevent electrical fires. Discover the...

Discover why some ovens cost more than others. Learn how features, build quality, and energy efficiency affect price. Find your...

Discover the best spots to install your wine cooler for convenience and style. Read CATA’s quick guide and find your...

Learn how to organise your wine cooler for better storage and perfect flavour. Discover smart tips to preserve your wines...

Ever wondered why hobs have no energy label? Discover the reasons behind this UK regulation and what it means for...

Discover smart space-saving appliance ideas for small flats and studios. Create a stylish, efficient kitchen without compromise. Read the full...

Learn what freezer burn is, how to prevent it, and keep your food fresher for longer. Follow these simple tips...

Tired of your integrated washer making too much noise? Discover practical tips to reduce vibration and quieten your appliance. Read...